What is the Film Faced Plywood?

In the construction world, Film Faced Plywood is often called “the workhorse” of the industry. While regular plywood is designed to be strong, film faced plywood is engineered to be indestructible and waterproof.1 If you are looking at a construction site and see dark, shiny, almost plastic-looking wooden panels holding up wet concrete, you’re looking

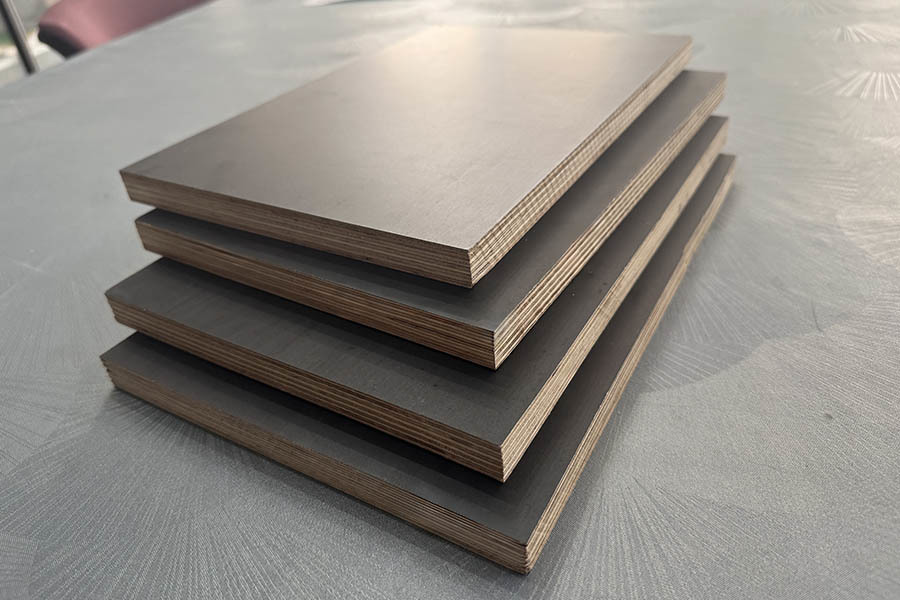

In the construction world, Film Faced Plywood is often called “the workhorse” of the industry. While regular plywood is designed to be strong, film faced plywood is engineered to be indestructible and waterproof.1

If you are looking at a construction site and see dark, shiny, almost plastic-looking wooden panels holding up wet concrete, you’re looking at film faced plywood.2

What Makes it Different?

The defining feature is the phenolic film (a thin layer of resin-treated paper) that is hot-pressed onto both sides of the board.3 This creates a hard, mirror-like finish that acts as a protective armor for the wood underneath.

Key Characteristics

-

Waterproof & Boil-Proof: It is often bonded with WBP (Water Boiled Proof) glue.5 This means the layers won’t come apart (delaminate) even if exposed to rain or soaked in water for days.

-

The “Mirror” Finish: The film is so smooth that it doesn’t stick to wet concrete.7 Once the concrete dries, you simply pop the plywood off, leaving a perfectly smooth “fair-faced” concrete surface that doesn’t need extra plastering.

-

High Reusability: Unlike standard plywood that might warp after one or two uses in the rain, high-quality film faced plywood can be reused 20 to 50 times if handled correctly.

-

Chemical Resistance: The phenolic coating protects the wood from the corrosive alkaline nature of concrete and other construction chemicals.

Common Applications

| Application | Why it’s used |

| Concrete Formwork | Creating molds for walls, columns, and slabs on construction sites. |

| Industrial Flooring | Used in truck trailers and van floors (often with a “wire-mesh” anti-slip texture). |

| Outdoor Furniture | Used for playground equipment and park benches because it resists rot. |

| Laboratory Benches | Because it is resistant to chemicals and easy to wipe clean. |

Smooth vs. Anti-Slip

You will generally find two surface types:

-

Smooth/Smooth: Used for concrete formwork to ensure a flat finish.10

-

Anti-Slip (Wire Mesh): One side has a textured, hexagonal, or cross-hatch pattern.11 This is primarily used for scaffolding platforms and truck beds where people need to walk without slipping.12

How to Tell Quality Apart

When buying film faced plywood, the color of the film often indicates the quality of the core:

-

Black Film: Usually the standard grade (often with a Poplar or Softwood core).

-

Brown Film: Typically indicates a higher-quality Hardwood or Birch core, offering more reuses and better strength.

Are you trying to decide between film faced and another type of plywood for a project? Tell me what you’re building, and I can help you weigh the costs!

Share this article

Follow us

A quick overview of the topics covered in this article.