The Essential Guide to Plywood: More Than Just “Cheap Wood”

The Essential Guide to Plywood: More Than Just “Cheap Wood” If you’ve ever walked through a hardware store or assembled flat-pack furniture, you’ve encountered plywood. It is one of the most versatile, ubiquitous, and misunderstood building materials in the world. While it often gets a bad rap for being a “fake” alternative to solid wood,

The Essential Guide to Plywood: More Than Just “Cheap Wood”

If you’ve ever walked through a hardware store or assembled flat-pack furniture, you’ve encountered plywood. It is one of the most versatile, ubiquitous, and misunderstood building materials in the world.

While it often gets a bad rap for being a “fake” alternative to solid wood, plywood is actually an engineering marvel that, in many cases, outshines its solid counterparts in strength and stability.

What Exactly Is Plywood?

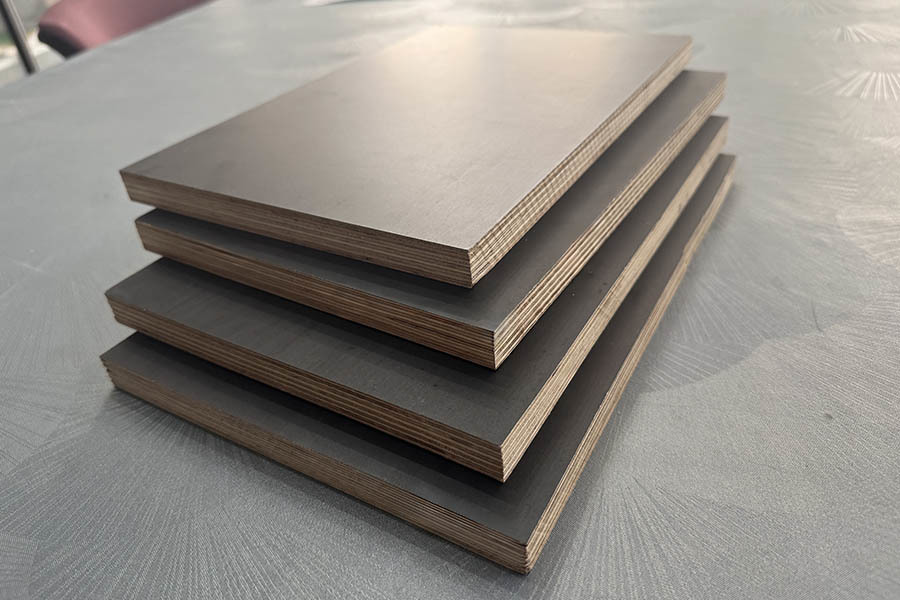

At its core, plywood is a manufactured wood panel made from thin sheets of wood veneer. These layers (called plies) are glued together under high heat and pressure.

The secret to its strength lies in a process called cross-graining. Each layer is rotated 90 degrees relative to the one below it. This alternating grain pattern provides structural integrity that solid wood—which can split easily along the grain—simply doesn’t have.

How Plywood is Made

-

Peeling the Log: Large logs are rotated against a long blade, peeling off a continuous thin ribbon of wood (like a giant pencil sharpener).

-

Drying and Sorting: These ribbons are cut into sheets, dried to remove moisture, and sorted by quality.

-

Gluing: The sheets are coated with resin (adhesive).

-

Layering: The sheets are stacked in odd numbers (3-ply, 5-ply, etc.) to ensure the panel remains balanced and resists warping.

-

Pressing: The “sandwich” is placed in a massive industrial press to bond the layers permanently.

Why Use Plywood? (The Pros)

-

Dimensional Stability: Because the layers pull against each other in different directions, plywood doesn’t shrink, swell, or warp nearly as much as solid wood when the humidity changes.

-

High Strength-to-Weight Ratio: It is incredibly strong for its weight, making it perfect for flooring, roofing, and wall sheathing.

-

Impact Resistance: The cross-laminated structure makes it very difficult to split, even when nailing near the edges.

-

Efficiency: Plywood allows for massive, seamless panels (usually 4×8 feet) that would be impossible or incredibly expensive to source from a single solid tree.

Common Types of Plywood

Not all plywood is created equal. The type you choose depends entirely on your project:

| Type | Best For… |

| Softwood | Construction framing, subfloors, and roof sheathing. |

| Hardwood | High-end furniture, cabinets, and decorative paneling (usually has a Birch or Oak finish). |

| Marine Grade | Boats and lakeside structures; it uses waterproof glue and has zero “voids” (holes) inside. |

| Aircraft Plywood | Extremely thin and high-strength, used for hobbies and specialty manufacturing. |

Is it Eco-Friendly?

Plywood is often considered a sustainable choice because it uses more of the log than traditional lumber milling. Modern manufacturing has also shifted toward low-formaldehyde or formaldehyde-free glues, making it safer for indoor air quality than it was decades ago.

The Bottom Line

Plywood isn’t just a “backup” for solid wood; it is a high-performance material designed to solve the natural weaknesses of timber. Whether you’re building a bookshelf or a house, understanding your plies is the first step to a successful build.

Are you planning a specific DIY project? I can help you figure out exactly which thickness and grade of plywood you’ll need for the job!

Share this article

Follow us

A quick overview of the topics covered in this article.